Blogs

The Green Cocoon VP Candace Lord joined Insulation Specialist Meaghan Stewart to clean up their local...

The Green Cocoon has the chance to win the Best of BBB award with our customers’ help to further stand...

Why use an insulation expert? Because when insulation isn’t installed correctly things happen! We received...

The Green Cocoon has received the Certificate of No Complaints and No Negative Customer Reviews from...

Recently, we were asked to take a look at a property and give a quote for insulation. We usually videotape...

The Green Cocoon is thrilled to be a part of this energy-efficient project in Arlington, Massachusetts....

On December 1st, two members of The Green Cocoon’s team attended Southern NH Home Builders and Remodelers...

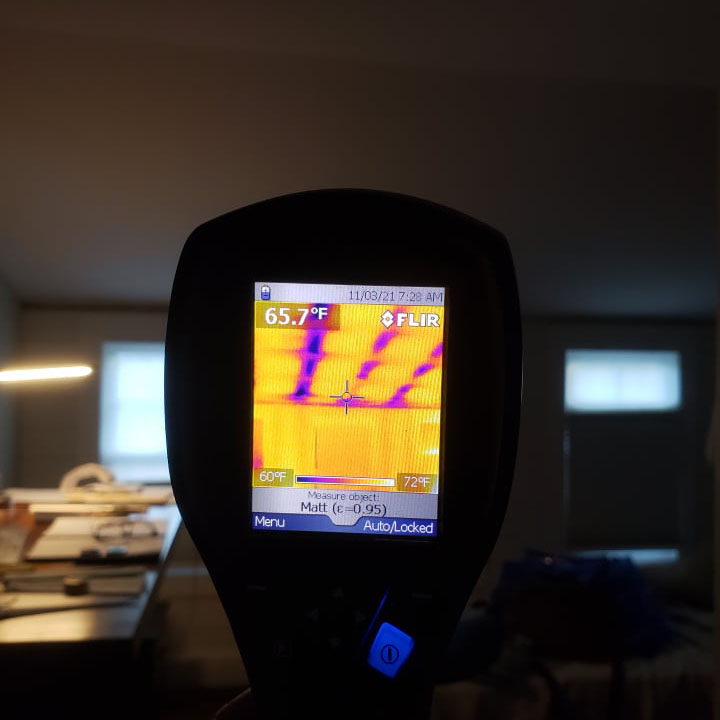

The Green Cocoon has many tools in its arsenal to help you stay warm and save you money. One of those...

No posts found