When you are ready to insulate your living space, you may be contemplating what R-value you will need. And why not? It is the most widely accepted measure of insulation and often aligns with a minimum code requirement. But assuming that your wall assembly will realize the R-value of your insulation ignores a crucial variable in building science—thermal bridging. Understanding and managing thermal bridging will make your living space more comfortable. And, it will save you money!

What is thermal bridging?

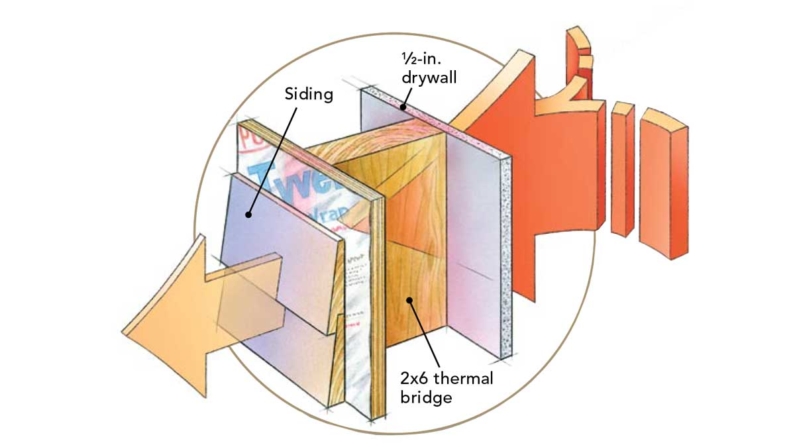

Thermal bridging is when a particularly conductive (or poorly insulating) material allows heat flow across a thermal barrier. Physics dictates that hot wants to go to cold and a thermal bridge is a perfect invitation. The best analogy is to think studs within an insulated wall. The insulation on either side of a stud will do its job of limiting heat flow. But, the wooden stud, which has a much lower R-value, will not. These bridges can become expressways of heat loss.

How does this work in a home?

How does this work in a home?

To understand and manage thermal bridging, let’s continue with the stud example. The typical R-value of a 2×4 wooden stud is 4.4, while the insulation on either side is much higher—typically greater than R13. The result of this bridge is heat being transferred and a significant loss in the wall’s effective R-value. In a wood stud wall with R20 insulation, thermal bridging can reduce the effective R-value to as low as R15. One of the worst thermal bridges is a metal stud. This can reduce effective R-value by as much as 80 percent. Along with studs, other typical building materials that create thermal bridges are metal fasteners, plates, headers, and windows. Typically, you can observe these all around a house—roofs, walls, fenestrations, for example.

The impacts of thermal bridging

If you are losing heat through thermal bridges, the efficacy of your climate control system decreases and uses more energy. Furthermore, these bridges can create cold spots within your walls where condensation can easily form. This moisture can produce a whole host of issues to the wall cavity—mold and mildew or rot, to name a few. Excessive moisture also challenges the structural integrity of your wall.

How do we prevent or limit thermal bridging?

Luckily advancements in building science and common sense can really help limit thermal bridging. Realistically, most homes will have some thermal bridging happening, but there are tools at our disposal to help prevent it.

- Exterior insulation – According to Havelockwool.com, a better term would be “out-sulation.” This means that by wrapping the exterior of your home in insulation you can prevent (or dramatically reduce) the common thermal bridging via wall studs. Cork is a great option. You can spray foam the exterior, add rigid board or Rockwool as well.

- Advanced house framing or Optimum Value Engineering – The goal of this building technique is to reduce lumber used in framing, which reduces thermal bridging. There are a lot of strategies incorporated, including spacing wall studs up to 24 inches on center, eliminating headers in non- load-bearing walls, designing on two-foot modules to make the best use of common sheet sizes, and to reduce waste.

- Insulated studs – The company T Stud produces an R19 stud that is a thermally broken, insulated wall stud assembly. They also have the BareNaked Tstud™, which is an uninsulated, thermally broken wall stud that you can insulate with the insulation of your choice. These studs can not only reduce thermal bridging, but they are incredibly strong.

- “Alternative” Wall Assemblies – Structural Insulated Panels (SIPs) are a common alternative to stick-built construction and can help limit thermal bridging. These panels have an insulated foam core between two rigid board sheathing materials, which when installed properly, can provide a continuous air and vapor barrier. There are issues, however, including the use of foam. Bamcore makes a bamboo wall system that is an environmentally friendly, extremely high-performance option.

Understanding and managing thermal bridging is easy

In conclusion, understanding and managing thermal bridging is a must because thermal bridging happens in every home. And, if you are constructing a new building, you can take care of that very easily. If you have older construction or renovation, you can use the best insulation possible in between the base to mitigate the amount of thermal bridging happening.

Contact us, and we’d be happy to answer all of your questions.

This article is based on an article from Havelockwool.com.

How does this work in a home?

How does this work in a home?